What is Investment Casting Tooling?

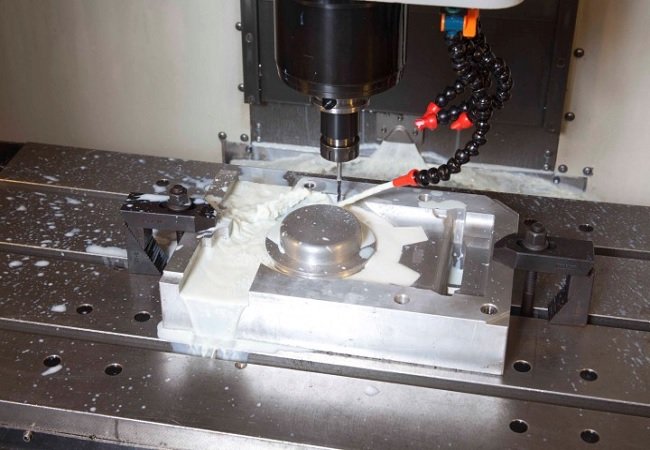

In metal casting and CNC machining, the term “tooling” describes reusable objects that are unique to each project. Wax-injection dies used to make wax patterns are referred to as tooling in the investment casting industry. Tooling is obtainable in simple single cavities or complex multi-cavity tools. It can consist of automatic ejectors for greater volume projects.

Ucasting maintains our tool and die capabilities. Our team can create precision tooling and dies. We used strong aluminum to make the wax-injection dies for investment casting. Moreover, we cast almost any part and tolerances within 0.005″ per inch. Our factory makes all of the tooling on-site, which lowers the cost of tooling. In order to satisfy every tool design and size, we adopt a wide variety of wax presses. You can ensure the quality and accuracy of our tooling.

Factors To Consider in Tooling Costs

- Part Size

- Part Volume

- Wax Cores

- Casting Complexity

- Tool Wear

Tooling Options For Your Project

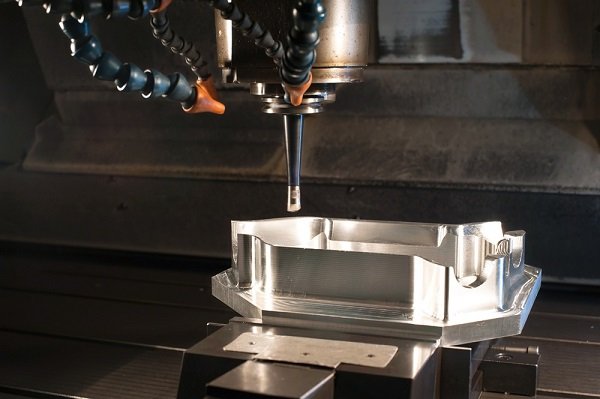

We make tooling in 3 different fundamental categories: automatic, semi-automatic, and manual. Each type of tooling has benefits and drawbacks of its own. If you can decide what tooling is ideal for your specific project, our team takes into account a variety of parameters, including part geometries and quantity needs.

Ucasting uses a variety of tooling choices for products with intricate internal geometry. In order to make sure your parts precisely match your designs, we employ loose inserts, collapsible mechanical cores, preformed ceramic cores, or soluble wax cores.

For the duration of the part, we will provide free tool maintenance. If you continue working with us on part-casting projects, we’ll repair and maintain your tooling. We also offer engineering services that might help you save time and money.

Contact us today!