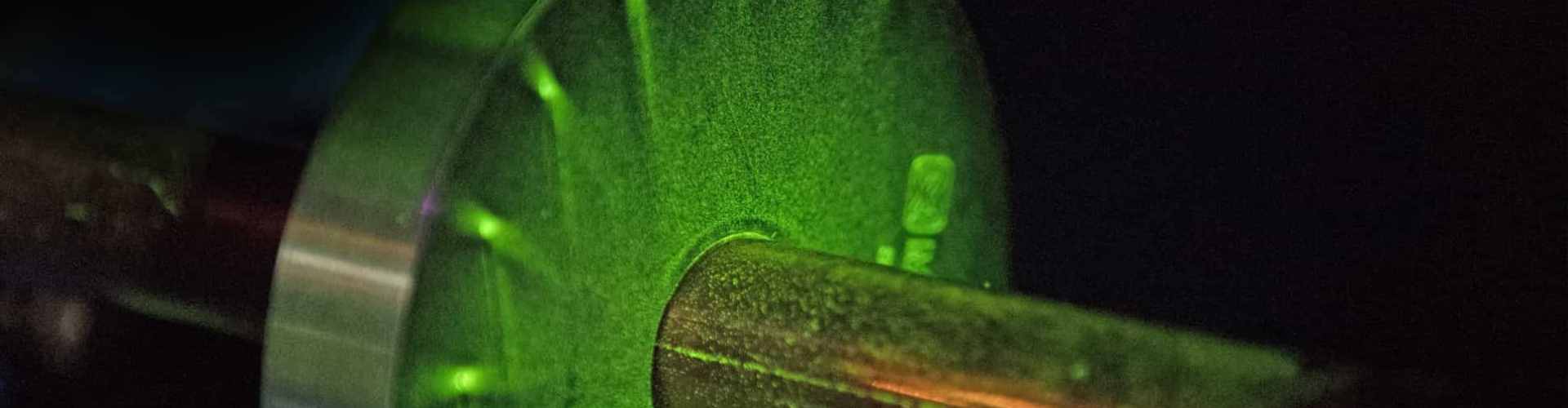

Magnetic Particle Inspection

MPI is an abbreviation for Magnetic particle inspection. It is an effective and non-destructive testing process that involved magnetic particles. These magnetic particles discover undetectable flaws without causing any damage to the component. It helps in finding outside casting defects such as inclusions, seams, porosity, cracks, etc.

Ferritic steels and irons are strongly magnetized metals suitable for this testing method. We can test the part automated and we have the capacity to perform high-volume production inspection.

If you have a magnetic particle inspection requirement, you can rely on Ucasting. We have an advanced inspection line that guarantees precise and fast services.

Magnetic Particle Inspection Advantages.

- Quick and comparatively simple.

- Simple or complex, small or large-size casting parts can be tested

- Can detect flaws immediately

- Shows surface and near-surface defects

- Cost-effective testing compare to other method