Material Testing

The fundamental characteristic of a metal cast part is its chemical composition. This composition has an immediate impact on the mechanical qualities of the finished products. Therefore, material testing is a crucial phase in the investment casting process to ensure quality production.

Ucasting utilized a spectrometer device to accurately and precisely measures the chemical content of the materials used in the investment casting process. The material for finished investment castings is approved if the value falls within the acceptable range for chemical composition. This procedure is known as “chemical analysis.”

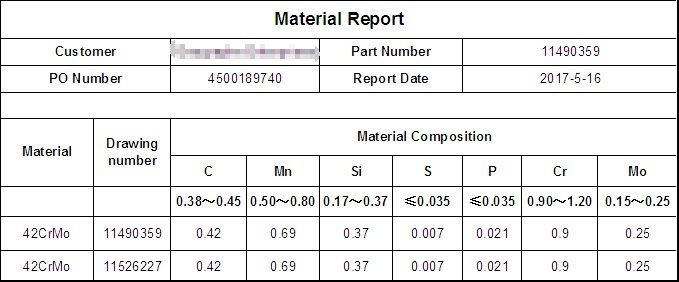

Material Report

A material report would display the spectrometer analysis findings. Our customer will receive this material report along with samples. Each batch of large investment castings production must, of course, pass a chemical test. The report will show what alloy elements make up a certain production batch and if this conforms with the standard.

Our spectrometer device is connected to a computer. It is saved on the network allowing for accessible information. If you want to trace your product, we can easily provide the details.

Additionally, we may offer additional testing of investment castings, including visual inspections, magnetic particle testing, hardness testing, dimensional testing, etc. Our customers will receive a high-quality product as a result of all these checks.