One-Stop Casting Services

The metal casting process involves molten metal that is poured into a hollow mold chamber. The mold is cooled to solidify the part. Casting is the best method for producing intricate parts that adhere to strict requirements. This process can enable a very high production rate with minimum secondary machining needed.

Ucasting specializes in different types of metal casting manufacturing processes. All of these procedures are carried out in sophisticated factories with a high level of specialization. Our team work in various metal material of your choice such as stainless steel, aluminum, iron and more. With many years of metal casting experience, we are dedicated to offering our customers the best and endless metal casting solutions.

Our Metal Casting Services

Sand Casting

- Resin Coated Sand Casting

- Clay Sand Casting

- Water Glass Sand Casting

Lost Wax Foam Casting

- Silica Sol Casting

Investment Casting

- Stainless Steel Casting

- Alloy Steel Casting

- Iron Casting

- Carbon Steel Casting

- Copper Casting

- Aluminum Casting

- Brass Casting

Aluminum Die Casting

Support Wide Industries

Depending on the needs of your business or project, Ucasting will assist in resolving any metal-related casting process. We offer industry-standard service from product creation to packing and delivery for our clients.

- Technology

- Mining

- Heavy Industry

- Aerospace

- Medical Industry

- Oil & Gas

- Automotive

- Machinery, etc.

Custom Casting Services Considerations

Casting service considerations should take into account:

- Parts quantity or production run size – Production run time and cost are influenced by tooling. Selecting the appropriate casting process can be challenging due to the benefits and drawbacks of each casting technique. Whether you need low- or high-volume production projects, you can rely on Ucasting.

- Custom specifications and industry norms – Our team is aware of industry compliance requirements for your casting application.

- Casting design – We have vast knowledge and expertise to design your casting product that meets your specifications. With a cost-effective casting mold and advanced manufacturing machines, you can save costs and make a higher profit.

- Casting material – Your casting project’s needs will determine the kind of material you select. Steel, stainless steel, aluminum, copper, zinc, magnesium, nickel, and a variety of alloys are common materials used for metal castings.

Casting Service Process

- Full Customization – According to the shape, material, size, surface finish, and other parameters and performance of the casting components, our skilled technical team will use advanced casting techniques to complete the order and provide an appropriate quotation.

- Mold Making – Ucasting offers a cost-effective mold-making process. We will create a precise mold of your products, produce a sample and send it to you. We support small and large-volume production to exceed your requirements.

- Production – Our factory always follows the ISO9001 quality management system. We own advanced machinery equipment and are supported by a skilled team to finish your order on time with minimal errors.

- Strict Quality Control – In every production procedure, Ucasting performs strict quality and inspection to guarantee the finest product outcome.

- Packaging – We offer different packaging services such as plastic boxes, cartons, wooden, etc.

- Delivery – We offer free transportation and warehousing services to save you money and time.

- After Service – Lifetime after-sales support is offered by Ucasting. Various solutions, including exchanges, returns, and replenishment are available. To ensure your satisfaction, specific measures will be discussed with one of our representatives.

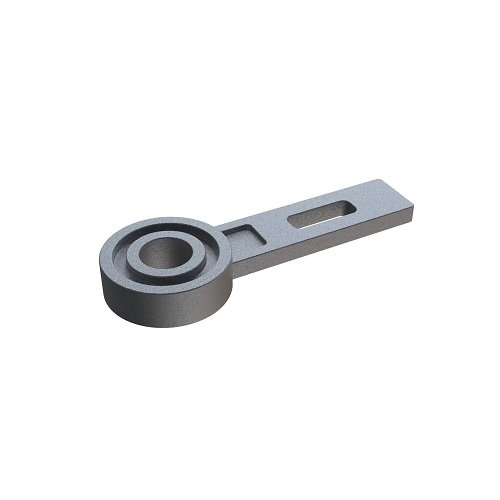

Some Casting Parts We Produced

- Gallery