What is Iron Casting?

Compared to steel, iron has a higher carbon proportion. The proportion ranges from 2% to 4.3%. It has an addition of manganese, silicon, and some impurities like phosphorus and sulfur.

Iron has excellent casting characteristics. Such characteristics include its ductility and high strength. This material is highly adaptable in the casting process for having a low cost and large quantities. The process of casting iron is often used for making complicated shapes.

Advantages of Cast Iron

Hardness

Our cast iron is depression- and abrasion-resistant. It is scratch-free guarantee and smooth as needed.

Fatigue-Resistant

The material can resist high stress at different cycles.

Toughness

Iron casting is robust, tough, and reliable. It also has high capacities for energy.

Versatile

The material can be changed shapes without the risk of breakage. It is important when producing complicated designs and shapes.

Elasticity

The material retracted to its original form after deformation.

Tensile Power

Iron casting can withstand high longitudinal stress without breakage.

High Strength

The material can be more ductile, rigid, and durable than pure iron. It makes them ideal for fabricating different materials.

Fluidity

Iron casting is easy to melt. The fluidity of the material makes the process simple. Thus, you can save money, resources, and time.

Useful

The materials are useful as they can mold in various sizes, shapes, and forms.

Low Maintenance

Due to its durability, flexibility, and strength, iron casting requires zero maintenance. It provides longevity without frequent repairs and replacements.

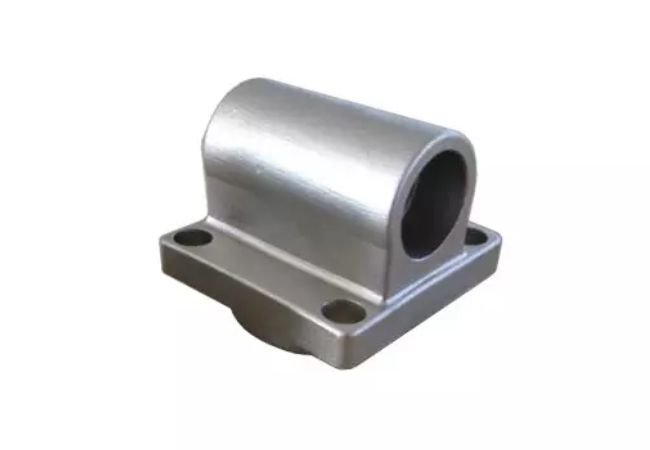

Iron Casting Process

Sand Casting

Sandblasting or sand molded casting is a process that includes non-reusable sand mold. This process can produce numerous sizes, shapes, and forms of iron-casting components.

Lost Foam Casting

Lost foam casting needs an evaporative-pattern concept. The foam has a low boiling point that can be used for the patterns. The good thing about lost foam casting is that it becomes simple and quick to finish.

Different Types of Iron Casting

Iron Casting Gray

It has a graphic microstructure characteristic, which allows it to have a gray look and causes breakage to the material. Iron casting gray is the most used cast iron type.

This material possessed 2.5% of chemical decomposition, 1% to 3% silicone, and 4% carbon. However, it has less shock-resistant and tensile strength than steel.

White Iron Casting

White iron casting has broke surfaces.

It is usually white because of its iron carbide precipitate.

Malleable Iron Casting

This type of iron casting starts as white.

It is then heat treated at 950°C temperature for a single or a couple of days.

Ductile Iron Casting

Ductile iron casting is also called nodular cast iron. This material has a tiny nodule of graphite. The characteristic of ductile iron casting is that it has no effect on stress concentration.

A Wide Variety of Applications

- Anchors for ships

- Pipe production

- Automotive parts

- Kitchen utensils such as pots

- Household appliances and tools