Carbon Steel Investment Casting Manufacturer

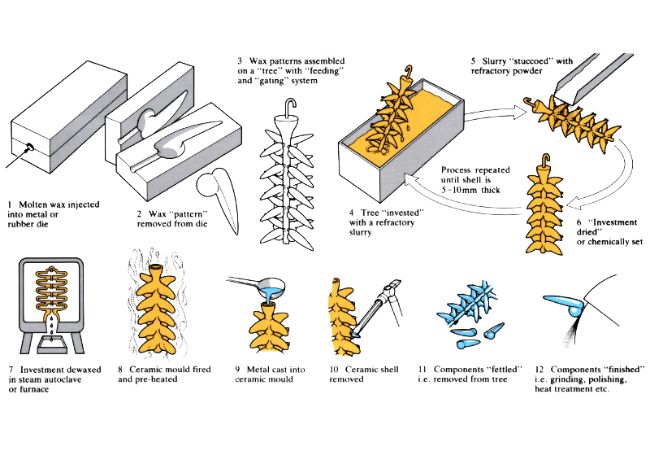

Carbon steel investment casting is a technique in which you utilize a wax pattern in shaping the mold. Here, you will use special type of mold to make parts from carbon steel.

So, which carbon steel are suitable for lost wax casting?

Carbon Steel Casting Grades

Some of the widely used carbon steel grades are as follows that you can use in the investment casting process.

| Types | Low Carbon steel | Medium carbon steel | High carbon steel |

| Carbon Content | 0.05%-0.25% | 0.29% to 0.54% | 0.55-0.95% |

| UTS | 400 – 450N/mm2. | 700 – 850N/mm2 | 800 – 1000N/mm2 |

| Elongation | 15% | 11% | 5-8% |

| HB | 120-180 | 200-300 | 250-400 |

More Resources:

Techniques In Carbon Steel Investment Casting Process

Two main processes exist when it comes to carbon steel casting. These processes are as follows:

- Silica Sol Investment Casting

- Water Glass Investment Casting

Silica Sol Investment Casting Carbon Steel

Silica sol investment casting is a technique that uses silica sol (solution). It acts as a binding material to facilitate carbon steel investment casting mold. The tolerance range of this casting method is within CT 5 to 6. In addition, the surface finish you will receive from this method is incredible.

The only thing that limits the use of silica sol carbon steel investment casting is the higher costs. However, this method is a perfect fit if you receive higher demand.

Water Glass Investment Casting Carbon Steel

Water glass investment casting uses water glass as a shell binder to facilitate carbon steel investment casting. Glass carbon steel investment casting provides end-casting carbon steel products within the tolerance range of CT 7 to 8. You can create complex carbon steel casting structures using this technique

How To Check Quality Of Carbon Steel Lost Wax Parts Standards

There are many ways of checking quality during the carbon steel investment casting process. Some of the main procedures include:

- Hardness test

- Penetration test

- Radiography test

- Welding assessment

- Heat treatment assessment

- Non-destructive testing

All these tests ensure that the carbon steel products quality is up to the mark or ready to ship.

Conclusion

Whenever you want to make accurate and precise carbon steel parts, consider silica sol investment casting or water glass investment casting.

So far, they are the best techniques.

At Ucasting carbon steel investment casting involves choosing best metal grade, part design, mold configuration, lost wax casting process and quality testing.

As a leading carbon steel lost wax casting company in China, we give you the benefits of cost advantages, fast turnaround and OEM support.

Contact us today for all your investment casting carbon steel needs.