What Is Investment Casting?

Investment casting is a unique metal forming technique where you form ceramic mold over wax pattern. You can also refer to the metal forming process as lost wax casting.

You will see how this works shortly.

But first, let’s quickly review:

We can trace the history of lost wax casting to 4000 and 3000 B.C. During this period Egyptians relied on this technology to make many parts and components.

However, the technology became popular after World War II. This was due to high demand for precise and complex components such as aircraft engines.

Since then, the process has changed with focus shifting to better technology. In fact, modern lost wax casting features:

- Ceramic shells

- Special dewaxing technologies

- Additive manufacturing technologies in mold design, just to mention a few.

Advantages Of Investment Casting Process

There are many reasons why you should consider investment casting technology. They include:

- Produces parts with precision and tight tolerances

- You can cast very complex parts with high degree of accuracy and precision

- Guarantees superior surface finish

- With proper design, it reduces the assembly costs and inconsistencies

- Low wastage and secondary machining reduces production costs

- It can handle both low and high production needs – this guarantees flexibility in the entire manufacturing process

- It can handle many alloys including ferrous, exotic alloys and non-ferrous alloys

- You can cast very thin parts – as low as ~ 0.015 in

Although there are many reasons why you should try this metal casting process it has some limitations.

Disadvantages Of Lost Wax Casting Technique

Even as you adopt lost wax casting technique, it is important to note the following:

- Extremely larger parts are suitable for other metal casting techniques

- Making the mold is a complicated affair

- Using specialized equipment to make mold may impact on the cost

- Casting parts with the following features may be a challenge:

- Parts which require cores

- Holes smaller than 1.6 millimeters

- Sections which are 1.5 times deeper than the diameter

With all these in mind, probably, you could be asking yourself:

When exactly should you choose investment castings?

Well, here is a quick checklist:

- When accuracy is an important design parameter – with this casting, tolerance can be as tight as 0.05 to 0.15. It depends on size and specification of the component.

- If the part is complex and has intricate shape or pattern

- In case the metal you want to cast is difficult to machine or fabricate

- When you are making parts which are difficult to cast using traditional metal casting such as turbine parts and components

- Whenever there are special performance requirements such as safety

- Evaluate the tooling cost – for low quantity, investment castings will be expensive. Of course, the casting technique may not be practical for very high production volume.

- Consider size limitations – with the advancement in technologies, you can make parts of different sizes and dimensions.

- Part structure size – the metal casting technique is best for thin-walled applications

The best part, Ucasting team is always here to help you get the best investment cast parts and components.

Simply tell us your requirements. Then, we will evaluate all the available options and recommended the best technology.

So, are there specific materials suitable for lost wax casting technique?

Let’s find out.

Know Investment Casting Material

Investment casting technique is suitable for virtually all types of materials. For example, you can cast any of the following:

- Carbon steel

- Stainless steel

- Zinc alloys

- Titanium

- Nickel alloys

- Cobalt alloys

- Aluminum alloys

- Copper alloys, just to mention a few.

Furthermore, you should note the following when handling different materials:

- It is a perfect choice for materials which are difficult to forge, machine or die cast

- At times, you may experience structural defects in some lost wax cast parts. You can eliminate porosity through HIPing. Also, heat treatment may improve the structural properties of cast metal parts.

- When handling reactive materials use carbon investment as opposed to the normal refractory

- The type of material also determines the refractory investment. It helps to reduce possibility of mould reactions.

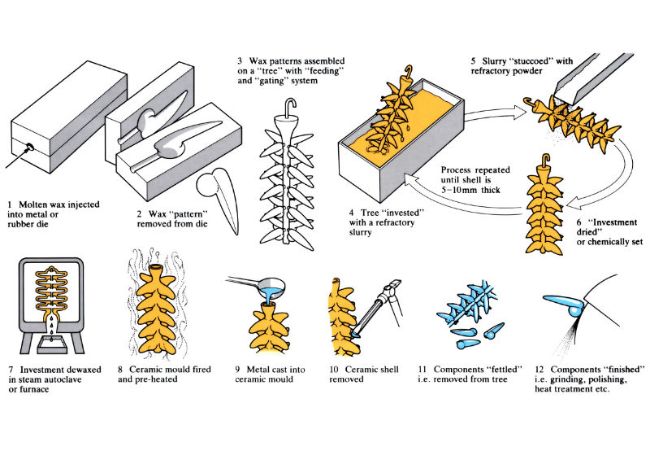

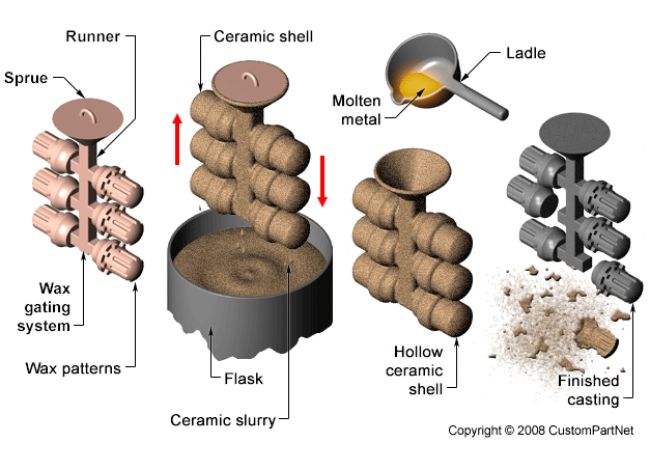

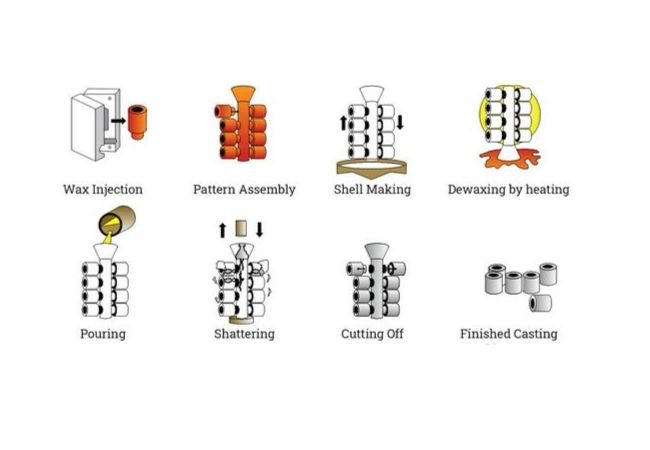

Step-by-step Investment Casting Process

Let’s look at the main steps in this casting process:

Step 1: Create A Pattern

Figure 3 Pattern for investment casting

From the part technical drawing, you will create a suitable pattern for your casting process. The pattern is a replica of the final product.

You can make the pattern using:

- Wax injection die or,

- 3D Printing techniques

Let’s loot these two options:

1. Create Pattern Using Wax Injection Die

You will design a mold from a suitable material. The best material for this type of mold is aluminum.

Once the aluminum mold meets your specification, inject wax in the mold. You should inject wax at high pressure.

You will choose the type of wax depending on:

- Ability to reclaim the wax

- Surface finish requirements

- Dimensional consistency

The most common types of waxes in this casting technique include;

- Filler pattern waxes

- Non filled waxes

- Runner waxes

- Water soluble waxes

- Sticky waxes

After injecting the wax, it will create a pattern.

Depending on the parts you wish to make, you can have one or multi-cavity.

2. Making Pattern Using 3D Printing Technology

You will use CAD software to design the type of pattern. Today, stereolithography is popular for making most patterns in lost wax casting.

A 3D printer will then print your pattern ready for next step.

Next, you will assemble the wax pattern. You should assemble the pattern into runners and finished tree.

Step 2: Dipping Wax Pattern In Ceramic

Once you are satisfied with the pattern, dip the finished tree in ceramic slurry. You should use only high-grade ceramic.

As a result, the ceramic slurry will form a shell around your wax tree. Once the ceramic form a reasonable thickness on the wax pattern, drop sand particles on its surface.

The sand helps to strengthen the wax assembly pattern surface.

You should repeat this process until you achieve a suitable thickness. Finally, you will allow the assembly to dry.

Step 3: Remove the Wax

Once the assembly dries, it is now time for dewaxing. You can use flash fire furnace or seam dewaxing autoclave to remove the wax.

The final product will be a complete mold. It is a replica of your pattern.

Step 4: Pour Molten Metal (Casting Process)

You will pour molten metal into the mold. Remember to preheat the mold cavity.

You will allow molten metal to cool and form shape your need.

Step 5: Removing The Pattern

You will remove your ceramic shell by hammer knockout or steel grit blasting. Then, you will cut the cast product from runner and gating system.

Step 6: Consider Surface Finishing

Although investment casting produce high quality parts, some surface finishing may be necessary. For instance, you may paint, coat or sand blast the cast component.

Step 7: Quality Inspection

You will inspect the final product for any defects. You should ensure dimensional consistency.

It should meet the exact specification as the technical drawing and requirements.

From the above 7 step, you can see the process is quite simple and straight forward. The only difference from other casting process is the wax.

Investment Casting Methods

Generally there are three main techniques in investment casting. They include:

- Water glass investment casting– It is known for low production costs. With this lost wax casting technique, surface finish is always Ra12.5 while tolerance is CT7-8. This casting method is very popular in China.

- Silica sol investment casting– Although the surface finish is better than water glass investment casting technique, it is costlier. Only 25% of companies in China use this method.

- Lost foam casting– This technique is suitable for mass production of parts and components. Additionally, automation is easier.

You can use this technique to create a range of decorative and complex components.

Applications Of Investment Cast Parts

Lost wax casting provides unlimited uses in many industries. Some of the most common applications include:

- Aerospace industry

- Locking systems

- Medical and dental industry

- Firearms manufacturing

- Food and beverage industry

- Hydraulic system

- Oil and gas industry

In short, lost wax casting is suitable for any industry which require manufacturing with:

- Precision and accuracy

- Low wastage of material

- Design flexibility

- Robust structure that can withstand fluctuating pressure and harsh working conditions

- Easy assembly and interlinking

Why Choose Ucasting As You #.1 Investment Casting Partner In China

Over the years have devoted ourselves to investment casting business. Our state-of-the art manufacturing equipment and capability makes us your perfect partner for all custom lost wax casting requirements.

From precision casting, to unmatched parts performance, we cast parts for any industry. Ucasting casting serve a range of markets, from aerospace, medical, dental to hydraulic industries.

Our engineers will help in the entire design process, reducing production cost while ensuring highest quality standards. Additionally, we support OEM clients, while supporting small business.

Contact us now for all your investment casting needs.

More Resources:

Investment Casting Manufacturing, Design & Materials

Investment Casting Vs. Sand Casting