Expert Investment Casting Foundry in China

Ucasting is a leading investment casting foundry in China with more than ten years of experience. We are providing one-stop solutions to different casting problems.

All our innovative casting services are offered at fast lead time and cost-effectiveness. We can provide a solution for your complex casting component that requires a few or large grams.

Ucasting also offers casting services for your short-run projects, rapid prototyping, and high-volume production.

With our rich experience, you can surely rely on Ucasting to skyrocket your projects.

Why Investment Casting

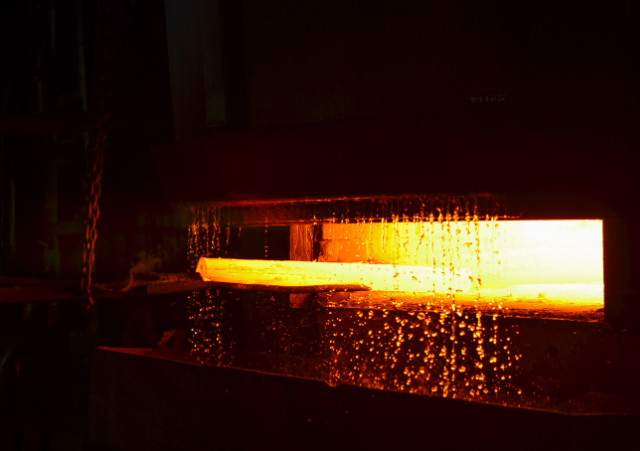

Investment casting can cut down the production process. Thus, providing a quick lead time while ensuring surface quality, high level of dimensioning precision, and does not require release angle. It also allows freedom of shapes and designs.

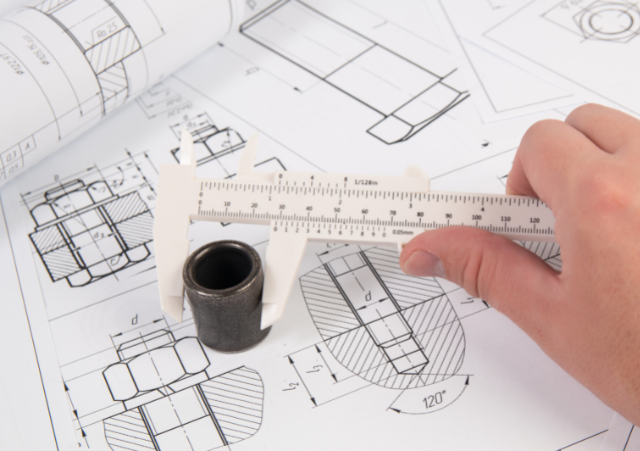

Investment casting tooling are designed through blueprints and other existing samples. We have professional tooling engineers knowledgeable in CAD file formats such as DFX, Solid, and more. You can guarantee tooling that has no additional charges.

Casting process allows tolerances according to VDG P690 standards. Class D1 for standard tolerance, Class D2 for precise tolerances, and Class D3 for extremely precise tolerance. All our casting services are provided through highly automated machines & production facilities.

Investment casting process is suitable for producing large or small casted components. Miniature and other small components with intricate features weigh 1/10 oz can be casted. However, it can also be used for producing components that weigh up to 50 pounds.

Featured Products We Cast

We provide valve body casting process with limitless shape possibilities. Our casting process allows different valve design flexibility with internal and external configurations to meet your specific requirements.

Ucasting offers investment casting processes for producing a wide range of agricultural wear parts with good wear resistance. We used high strength materials along with lost foam or lost wax process.

We designed bucket teeth based on your dimension and design requirements. These parts are produced through different processing including lost wax casting, wax pattern injection, tree assembly, and more.

Our casting process allows us to fabricate a wide range of axle boxes, yokes, axle bod housing, door hinges, center plates, pedestals, and bearing brackets for railway infrastructure or rolling stock.

Ucasting offers pump casting processes using various metals. Through this process, we can produce different parts such as pump lodging, pump body, pump mounting section, and more.

We offer corner casting that is compliant to ISO1161 standards. You can provide top left casting, top right casting, bottom left casting, and bottom right casting. We used different materials including steel.

Why 1000+ Global Client

Trust Ucasting

- R&D

- Materials & Standards

- Finishing

- Quality Control

- Heat Treatment

R&D

Ucasting has a professional team of R&D for developing follow-up treatments, optimized materials, and enhanced processes.

Our R&D team has years of experience in providing a stable casting process and prototype for testing.

With our research and development team, Ucasting is able to provide lightweight design and complex casting.

Materials & Standards

The most important part of providing product functionality is choosing the best materials.

A good investment casting also depends on the material choice.

Here at Ucasting, we can help you find the right material with maximum heat resistance, tensile strength, chemical composition, and more.

Finishing

Depending on the material used, our precision casting roughness ranges from Ra 1.6 up to 6.3µm.

Lower roughness can be cost-saving since it does not require additional processing.

However, surface treatments also allow appearance improvement, enhanced surface properties, and a layer of protection.

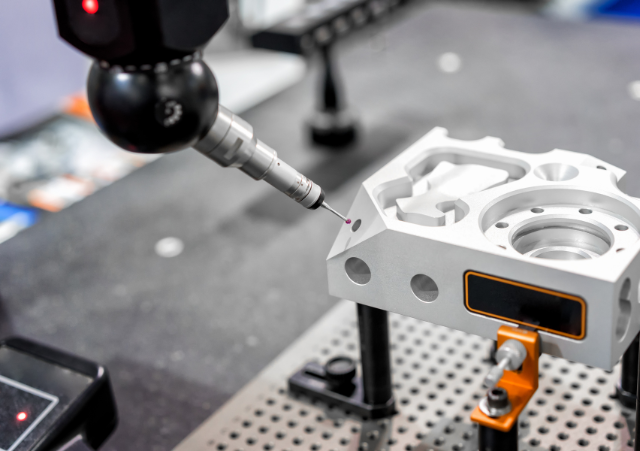

Quality Control

Ucasting has an in-house control system to inspect every production stage.

We are also equipped with advanced testing instruments including impact testing, Spectrograph, MT instruments, Brinell and Rockwell hardness tester, and more.

In addition, Ucasting also conducts material testing, X-ray testing, and magnetic particle inspection. We will provide free samples before each mass production so you can check the quality.

Heat Treatment

We are able to attain the different component properties through heat treatment.

It is one of the main technologies that are used during the process of investment casting.

Ucasting offers different heat treatment processes including normalizing, annealing, tempering, quenching, carburizing, hardening, case hardening, and more.

If you need a one-stop heat treatment service, don’t hesitate to contact us!

Industry We Recently Served

Frequently Asked Questions

Investment casting is also called as precision casting. This process includes industrial lost wax that is used for manufacturing small metal components.

The most common alloys we use for this process includes carbon steel, ductile iron, stainless steel, aluminum, and more. However, we can also use materials according to your specific selections.

Yes. Ucasting does not have quantity requirements. Infact, we also accept small quantity trial orders.

Usually, the lead time for our investment casting may take 20 to 30 working days. For batch production, it also ranges from 25 to 35 working days.

We used split aluminum die or tool for producing a wax pattern. However, tooling for die casting, stamping, forging, and other processes is more expensive.

Yes. We offer other machining services to ensure tighter dimensional tolerances.

Our investment casting allows affordable tooling cost. It also provides flexible designs, broad material selection, and no quantity limitation, and flexible designs.